Trafigura, Aurubis and Kamoa Copper Complete First Sale of Low-Carbon Refined Copper via the Lobito Atlantic Railway

Trafigura has completed the first sale of low-carbon-intensive copper anodes produced by Kamoa Copper to the Aurubis Group, a leading global provider of non-ferrous metals with best-in-class sustainability standards. This initial delivery marks a significant step towards producing some of the world’s lowest-carbon refined copper.

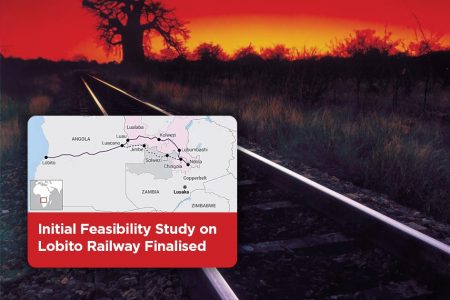

The anodes have been delivered to Trafigura’s dry port facility in Kolwezi, Democratic Republic of the Congo (DRC), and will be transported via the Lobito Atlantic Railway (LAR) in the coming days. From there, the copper anodes will be shipped from the Port of Lobito to Aurubis, for use in its European refining operations. LAR provides the shortest route from Kolwezi to an African port, reducing inland transit times to just seven days.

The copper anodes were produced in the recently commissioned state-of-the-art copper smelter at the Kamoa-Kakula Copper Complex in the DRC. The smelter incorporates cutting-edge direct-to-blister technology supplied by Metso Outotec. The Kamoa-Kakula Copper Complex has been assessed to be the world’s lowest carbon-emitting major copper mine.1

Kamoa Copper operates the Kamoa-Kakula Copper Complex as a joint venture between Ivanhoe Mines and Zijin Mining. Trafigura is one of three offtakers for the copper anodes produced by the Kamoa-Kakula smelter. Once ramp-up is complete, the Kamoa-Kakula smelter will be capable of producing up to 500,000 tonnes per year of 99.7%-pure copper anode, making it the largest copper smelter in Africa.

Gonzalo De Olazaval, Head of Metals, Minerals and Bulk Commodities, Trafigura, commented: “Bringing together Trafigura, Aurubis, Kamoa Copper and the Lobito Atlantic Railway to complete the sale and transport of low-carbon copper anodes from the DRC shows what the mining supply chain can achieve when it works together.”

“This transaction reflects the strength of our long-standing relationships with Aurubis, a world class company in its field, and Kamoa Copper, whose state-of-the-art smelter is among the least carbon-intensive in the industry — a testament to the world-class operation it has established in the DRC.”

“We are equally proud that these anodes will be transported via LAR —a milestone made possible by the vision and support of the governments of the DRC and Angola, as well as the loan package provided by the U.S. International Development Finance Corporation (DFC) and the Development Bank of Southern Africa (DBSA).”

Ivanhoe Mines’ Founder and Executive Co-Chairman, Robert Friedland, commented: “The first shipment of 99.7%-pure copper anodes marks another milestone for Kamoa-Kakula and for Africa’s rapidly advancing infrastructure. The Lobito Atlantic Railway has become a transformational gateway linking the extraordinary mineral wealth of the DRC with global markets at unprecedented speed and efficiency.”

“Copper produced at Kamoa-Kakula, transported via the Lobito Atlantic Railway and refined in Aurubis’s industry-leading low-carbon facilities in Europe, represents a new paradigm in the creation of the greenest and most sustainable refined copper supply chain serving global markets. Combined with our state-of-the-art smelter, this integrated supply chain is setting a new global benchmark for low-carbon-intensive copper for generations to come.”

In 2025, LAR transported more than 200,000 tonnes of cargo to and from the Port of Lobito. In January 2026 alone, 30,000 tonnes were transported, and the Port of Lobito received a record 50,000-tonne bulk sulphur vessel.

Volumes are expected to continue increasing steadily throughout the year, as LAR establishes itself as a reliable, high-capacity export route.

*1 According to an independent assessment by Skarn Associates and WSP Group.