This content is for Premium Subscribers only. To view this content, login below or subscribe as a Premium Subscriber.

Related News Articles

Tanzania SGR Mwanza–Isaka Progress Update

27 February 2026

East Africa, Tanzania

1 min

TRC Officially Launches Container Transport Services Using SGR

20 February 2026

East Africa, Tanzania

1 min

TAZARA To Receive US$15m A Year Under CCECC Concession

20 February 2026

SADC, Zambia

1 min

TRC Ends Subsidy Reliance as Tanzania Advances Transport Reform Agenda

13 February 2026

East Africa, Tanzania

1 min

1 min

Tanzania’s Malagarasi Bridge Reaches 96 Percent Completion under SGR Phase 2

05 December 2025

East Africa, Tanzania

1 min

East Africa’s Rail Corridors Gain Momentum as EAC Shares Updates in Luanda

21 November 2025

East Africa, Tanzania

1 min

TRC and TCB Launch SGR Ticket Payment Card

18 October 2025

East Africa, Tanzania

1 min

SPV to Manage TAZARA’s Freight Operations

18 October 2025

SADC, Zambia

3 min

Government Assures China Railway CRCC of Support in TAZARA Revitalisation Process

30 September 2025

SADC, Zambia

1 min

Zambia, Tanzania and China Sign $1.4 Billion TAZARA Revitalisation Agreement

30 September 2025

SADC, Zambia

1 min

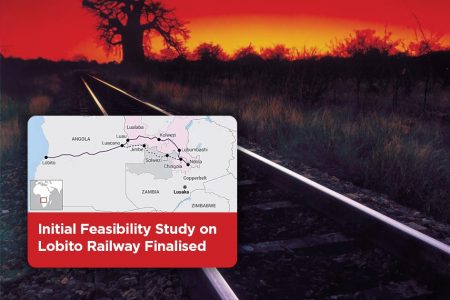

Initial Feasibility Study on Lobito Railway Finalised

29 September 2025

SADC, Zambia

2 min

Zambian President Says Negotiations for TAZARA Concession Concluded

22 September 2025

SADC, Zambia

1 min

Tanzania Railways Corporation to Create 2,460 Jobs

25 August 2025

East Africa, Tanzania

1 min

Tanzania–Burundi SGR Construction Begins

24 August 2025

East Africa, Tanzania

1 min