This content is for Premium Subscribers only. To view this content, login below or subscribe as a Premium Subscriber.

Related News Articles

1 min

Lobito Atlantic Railway Secures USD753 Million to Accelerate Development in Angola

18 December 2025

SADC, Zambia

1 min

Zambia’s Mutanda–Kaoma Road Project Set to Transform Mining and Agricultural Trade

12 December 2025

SADC, Zambia

2 min

Dangote Cement Zambia Sees Opportunity in NRZ Clinker Transport

12 December 2025

SADC, Zimbabwe

1 min

TAZARA Revitalisation Launch Highlights Enduring Zambia, Tanzania and China Partnership

21 November 2025

SADC, Zambia

2 min

EU Boosts Zambia’s Rail Revival with €50 Million Investment

14 November 2025

SADC, Zambia

2 min

EU Expands Engagement in the Lobito Corridor under Global Gateway Initiative

14 November 2025

SADC, Zambia

2 min

Botswana Unveils Plans to Modernise Infrastructure and Expand Rail Connectivity

02 November 2025

SADC, Zambia

2 min

Zambia Railways Would Require Seven Years to Construct New Railway Line

24 October 2025

SADC, Zambia

2 min

SPV to Manage TAZARA’s Freight Operations

18 October 2025

SADC, Zambia

3 min

IFC Seeks Consultant for Zambia Lobito Corridor Investment Mapping

10 October 2025

SADC, Zambia

1 min

Government Assures China Railway CRCC of Support in TAZARA Revitalisation Process

30 September 2025

SADC, Zambia

1 min

Zambia, Tanzania and China Sign $1.4 Billion TAZARA Revitalisation Agreement

30 September 2025

SADC, Zambia

1 min

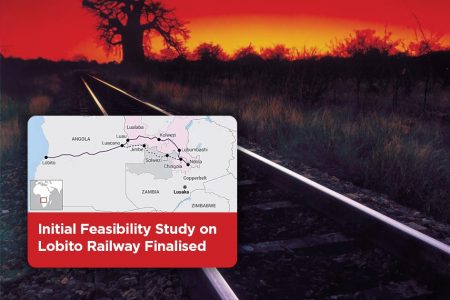

Initial Feasibility Study on Lobito Railway Finalised

29 September 2025

SADC, Zambia

2 min

Joint Communiqué Issued at Conclusion of Kazungula Bridge Project Ministerial Meeting

29 September 2025

SADC, Zambia

1 min

ZRL, Zambia Sugar Plc Confer On Strengthening Long-Standing Business Relationship

22 September 2025

SADC, Zambia

1 min